How To Repair A Chimney Crown.

- Home

- Chimney Guide

- Chimney Crown Replacement

Chimney Crown Replacement

This post may incorporate affiliate links and so I earn a committee.

Chimney crown replacement may be necessary if your chimney crown, also known every bit the top plate or a chimney cap, is cracked or damaged.

The crown plays a vital role in the protection of your chimney past sealing off the peak portion of your chimney and shedding water abroad from the masonry construction.

Why do a lot of chimney crowns fail over time? Many crowns are poorly constructed correct from the start.

Crowns built out of thin mortar without proper reinforcement will somewhen crack over time due to temperature changes and weather weather condition.

Every bit the chimney crown deteriorates it causes 2 things.

First, it allows wet to run downward into the masonry structure of the chimney causing spalling on the exterior bricks.

This moisture likewise causes the bricks to separate and eventually fall autonomously.

Second, h2o can run between the crown and the chimney flue causing damage to the clay tile or even worse, causing damage to the chimney damper, smoke sleeping room, or the fireplace itself.

Building The Perfect Chimney Crown

Proper chimney crown replacement requires a few important steps which will substantially increase the life of the crown.

Hither are a few details to consider:

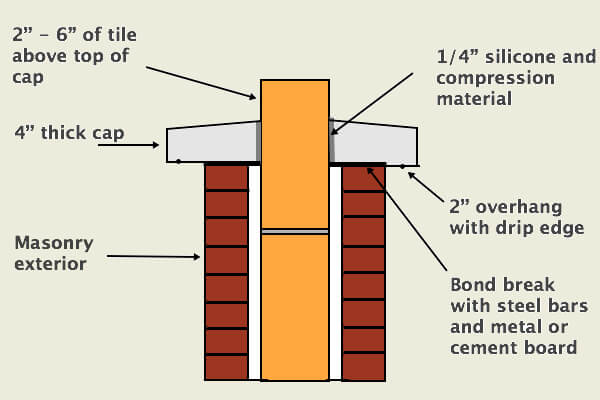

Do non brand the crown flush with the outside chimney wall.

The crown should extend at least ii'' past the exterior wall and contain a baste edge underneath.

Use physical for construction non mortar. Concrete is stronger and can withstand temperature fluctuations and weather exposure better than mortar.

For extra strength, ane''x 1'' wire mesh should be placed in the concrete during the cascade. Lay the wire mesh half way through the pour then it's in the center of the physical.

Cut the mesh slightly smaller than the crown then it'southward not exposed to moisture which will lead to rust, peradventure causing the crown to scissure.

The crown should be at least 4'' thick and accept a slight outward gradient to shed water away from the chimney flue.

The concrete crown should not come into contact with the flue.

During construction the flue should be wrapped with a compression material to allow a 1/four'' separation between the concrete crown and the flue tile.

Silicone sealant should be added to the i/4'' separation to prevent water damage.

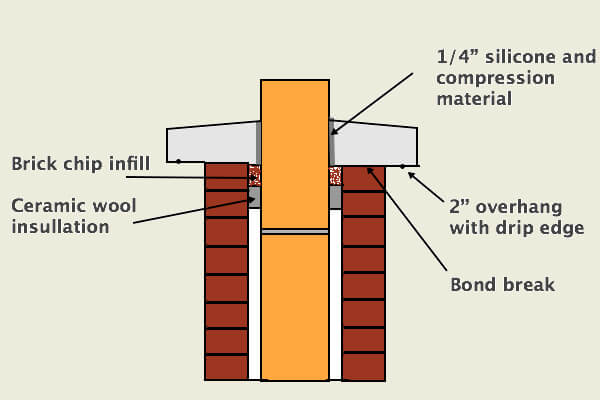

Ceramic wool insulation makes a keen pinch material.

Since the concrete and the flue will aggrandize and contract at different rates, this expansion gap will prevent impairment to both the flue tile and the crown.

Course a bail pause.

Use steel support bars to form a grid pattern from one side of the masonry wall to the other.

Then lay sheet metal or cement board beyond the metallic supports to form a thin bail interruption betwixt the chimney crown and the masonry walls.

This serves two purposes. Get-go, without the barrier the cement will just run down the chimney structure filling the airspace between the flue and the masonry walls.

Second, it allows the masonry walls and the concrete crown to expand and contract at different rates, reducing the possibly of them cracking.

When edifice the bond break don't employ plywood or other similar materials.

Wood is non merely combustible, but it will soak up moisture which will aggrandize when information technology freezes causing the crown to crack.

Instead of steel back up confined and sail metallic, some contractors choose to use ceramic wool insulation to fill the void between the masonry walls and the flue.

Then brick fleck is added on pinnacle of the insulation and felt is laid for the bond break.

The elevation of the flue liner should extend at to the lowest degree 2'' by the meridian of the crown but no farther than vi''.

Cheque your local building codes to meet what'due south recommended in your area.

Chimney Crown Replacement - Forms

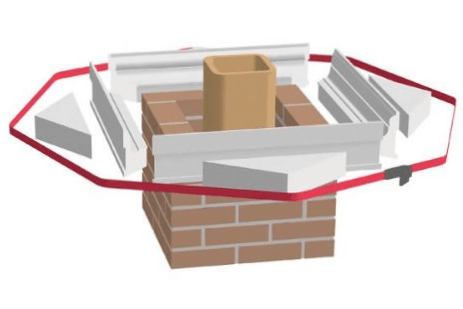

Since y'all'll be pouring concrete to construct the crown you'll either accept to build your own form out of woods or buy one.

Building a class is often time consuming and dependent on your carpentry skills.

To make things easier you tin purchase adjustable steel forms or foam forms that can be cut or adapted to fit your chimney.

Steel forms are the fastest and most user friendly blazon of form.

Since they're adjustable you tin quickly and easily size them to fit a variety of chimney shapes.

Plus, they're reusable and should last many years if properly cared for.

The downfall of using steel forms is the cost.

Many forms are sold in pairs meaning you'll demand to purchase 2 pairs to create a 4 sided form.

A adept release agent should be practical to the form to prevent the form from sticking to the concrete.

Many homeowners volition only use the course in one case so the price of a steel class may not outweigh the convenience they offer.

Although they require a little more setup, cream forms are much cheeper than steel forms.

Plus, they usually have a built in drip edge and artful shape.

Cream forms offering convenience without spending a lot of money.

To use one, the cream must be cut and shaped to the dimensions of your chimney.

The foam forms tin besides exist reused multiple times if needed. No matter which style of form you use, thoroughly clean the form afterwards each use.

Overall - Chimney Crown Replacement

If washed properly, chimney crown replacement is a project that most homeowners tin can consummate on their own saving you hundreds of dollars in labor.

Plus, your new chimney crown replacement will finer shed water and protect your chimney and fireplace from serious harm for many years.

How To Repair A Chimney Crown.,

Source: https://www.firewood-for-life.com/chimney-crown-replacement.html

Posted by: millermagand.blogspot.com

0 Response to "How To Repair A Chimney Crown."

Post a Comment